Treatment And Corrosion Control Of Cooling Water AquaEnergy Expo Knowledge Hub

Corrosion Control Oyis Engineering Services Limited

NACE CORROSION CONTROL IN THE REFINING INDUSTRY The world's leading source of training and information on coating inspection organized by IMC engineering S.r.l. The Corrosion Control in the Refining Industry course provides methods of corrosion control through material selection and designing a systematic method for applying the technology of.

Corrosion Control

Even with this corrosion engineering program, curricula primarily focus on science and technology of corrosion processes and mitigation and corrosion control, rather than corrosion management. This pertains to the foundational levels (1 and 2) of the CMS Pyramid, and there is little or none related to the mid and upper levels of the pyramid (Levels 3 to 6).

Cost Of Corrosion In The Oil And Gas Production Industry

NACE Trinidad & Tobago 2018 Schedule. In the Corrosion Control in the Refining Industry course, get an overview of refinery process units and specific process descriptions, and learn to recognize corrosion and metallurgical problems that occur in process units. With this course, you gain valuable information to be used on the job.

Corrosion Control in Refining Industry Oil Refinery Cracking (Chemistry)

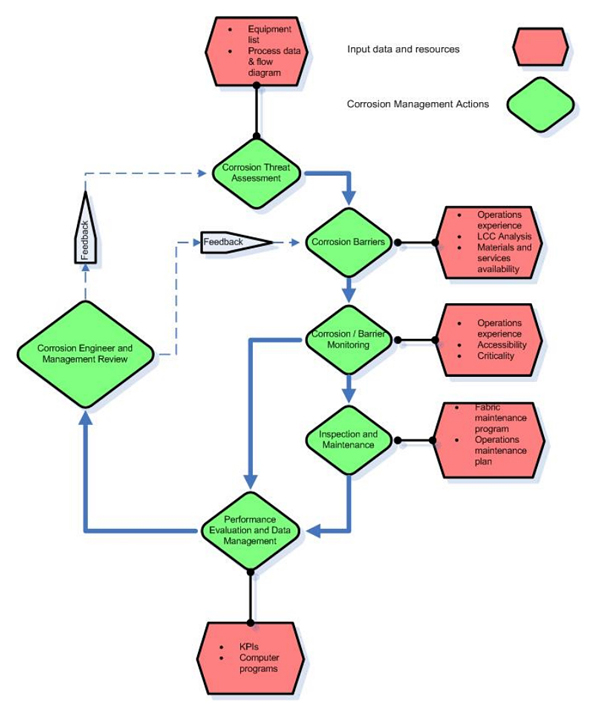

NACE International initiated the International Measures of Prevention, Application, and Economics of. Corrosion Technologies (IMPACT) study to examine the current role of corrosion management in industry and government and to establish best practices. The global cost of corrosion is estimated to be US$2.5 trillion, which is equivalent to 3.4.

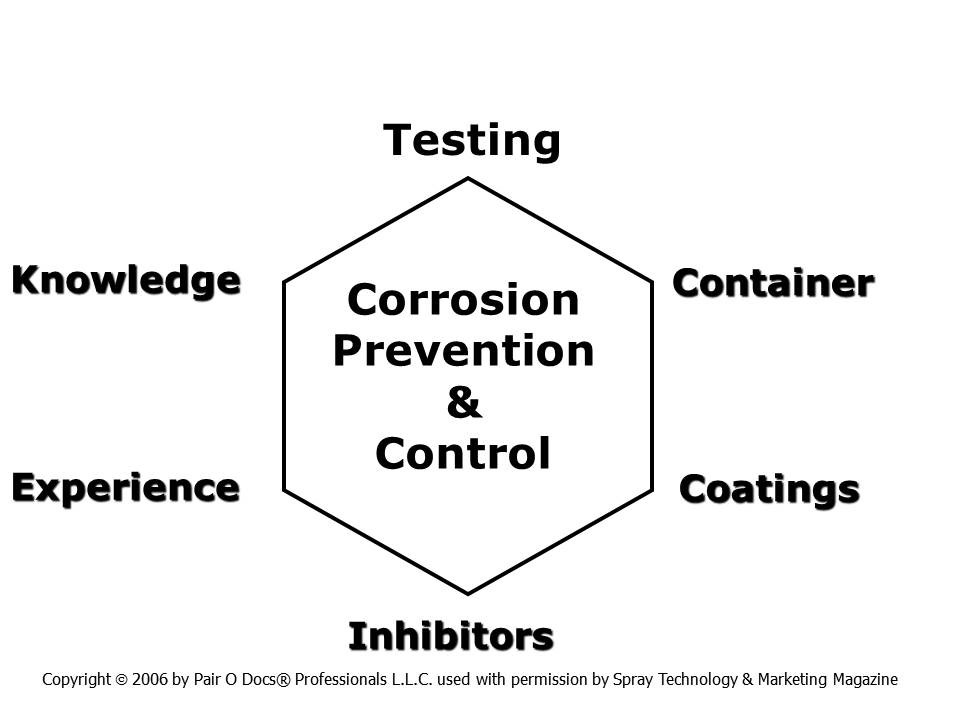

Corrosion control is a process, not a event

The term corrosion comes from the Latin word corrodere, which means "to gnaw to pieces." From a safety perspective, in a:.European Commission study of refining accidents around the world traced to corrosion, 76% resulted in fires or explosions. They cite other statistics such $2.5 trillion or 3% of global GDP as the economic cost of.

Treatment And Corrosion Control Of Cooling Water AquaEnergy Expo Knowledge Hub

NACE International Publication 34103 (2014 Edition) This Technical Committee Report has been prepared by NACE . International Task Group (TG) 176,. The terms "sulfidic corrosion" and "high-temperature sulfidic corrosion" used in many refining industry technical references on this subject refer to this same damage mechanism and are.

Refining Corrosion Technologist NACERCT001 Cathodic Protection Technologist The exam

In today's refining industry, ammonium chloride (NH 4 Cl) corrosion is one of the leading causes of equipment and piping failures. Because of the associated material, maintenance, and repair costs, NH 4 Cl corrosion has a devastating impact on refineries. It can also wreak havoc on the structural integrity of the refinery and jeopardize the.

PPT Corrosion Control in the Refining Industry Certification PowerPoint Presentation ID11894801

The Corrosion Control in the Refining Industry course provides an overview of refinery Process units and specific process descriptions. It also focuses on the examination and identification of metallurgical problems that occur in process units. Students receive REFIN - COR software, which is a database of experiences, problems, and solutions.

(PDF) Corrosion control and surface finishing environmentally friendly approaches

Refining Industry. The total annual cost of corrosion in the oil and gas production industry is estimated to be $1.372 billion, according to a NACE study. That figure can be broken down into $589 million on surface pipeline and facility costs; $463 million annually in downhole tubing expenses; and another $320 million in capital expenditures.

It is time for corrosion professionals to “lead corrosion control” rather than the mostly used

The Refining Corrosion Technologist certification is targeted at individuals who are responsible for identifying, locating, and controlling corrosion in refinery environments. Those applying for this certification should possess an understanding of refinery process unit-specific corrosion mechanisms. From the proximity of assets to saltwater.

Essential Elements of a Successful Corrosion Management Program

The total annual cost of corrosion in the oil and gas production industry is estimated to be $1.372 billion, according to a NACE study. That figure can be broken down into $589 million on surface pipeline and facility costs; $463 million annually in downhole tubing expenses; and another $320 million in capital expenditures related to corrosion.

(PDF) Development of Sustainable Inhibitors for Corrosion Control

Course Topics. The following topics are included in Corrosion Control in the Refining Industry: Corrosion and Other Failures . Crude Distillation and Desalting . Fluid Catalytic Cracking Unit . Cracked Light Ends Recovery (CLER) Units . Hydrofluoric Acid Alkylation Units . Sulfuric Acid Alkylation Units . Corrosion in Hydroprocessing Units .

Corrosion And Its Control UNIT II. Corrosion It is the degradation of a material due to a

Corrosion control is a major challenge in the crude oil refinery sector. The presence of water, acid, oxygen, and brine all make for the ideal corrosion environment.. This chapter aims to identify and examine corrosion issues in the refining industry and their solutions.. benzimidazole as a CO 2 corrosion inhibitor for X60 steel in NACE.

(PDF) Stress Corrosion Cracking Guides to Good Practice in Corrosion Control Shree Bubesh

REFIN•COR, which is an online software database of experiences, problems, and solutions encountered by refining industry corrosion engineers and includes minutes of meetings of NACE Committee TEG 205X (formerly T -8) on Refining Industry Corrosion from 1957 through 2011. This is information which can be used on- the-job and cannot

Pictures Corrosion Control International

Corrosion in Refineries: Corrosion Inspection, Corrosion Monitoring and Corrosion Control for the Refining and Petrochemical Industry, presented by NACE certified Corrosion Specialist . WebCorr has over 40 corrosion courses for you to choose from for In-House Training, Online and Distance Learning.

Corrosion Control & Management Production Chemistry Training

INTRODUCTION ABSTRACT. Corrosion by wet ammonium chloride salt is a significant concern in many refining process units. Because corrosion rates typically experienced can be extremely high when all of the conducive conditions are met, every attempt is made to prevent this corrosion from occurring. This includes process design, corrosion resistant materials, and source control of chlorides.

.